The grinding and polishing of the inner wall of the round tube is currently the main use of mechanical polishing and electrolytic polishing of two kinds, of which the mechanical polishing method is used most.

I. Mechanical polishing

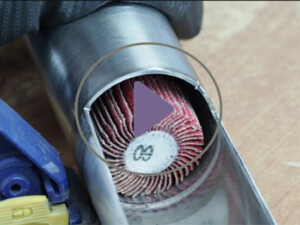

Use the thousand leaf wheel or sand belt, through the straight grinder or large polishing machine, with a long throwing rod extended into the tube, driving the thousand leaf wheel high-speed rotation, to achieve the effect of polishing and sanding of the inner tube.

Main materials: Thousand-blade wheel, abrasive belt, black diamond grinding wheel, handled janitorial cloth wheel, polishing paste, cloth wheel and other abrasive products.

Smaller steel tubes are polished on the inside:

1. Use a straight grinder with a mill wheel to grind the weld channel, use 60#, 120# for rough grinding respectively.

2. Use the cleaning cloth/black diamond abrasive pad to polish the scratches with 240#, 320# and 600#.

3. Use polishing paste with a cloth wheel for rough polishing to make the polished area smooth and shiny.

4. Use clean cloth wheel to remove dust and other traces to achieve mirror effect.

Thousand leaf wheel and abrasive belts, the main role of grinding welded seams, remove impurities in the pipe wall, including rust.

Parker Cloth Sanding Wheel Usage:

After conventional sanding, the material line pattern is not clear, the

traces are left after welding channel grinding, cutting and rough grinding.

Usually after sanding and then use the medium-grained Pepsi Cloth, the sanding surface pressure is more evenly distributed to the surface of the pipe fittings.

The higher the grinding pressure, the clearer the line pattern.

Black Diamond Grinding Wheel Usage:

Removal of oxides and dirt before and after welding and welding of metals;

Removal of various surface coatings, protective and insulating paints, widely used in the automotive industry;

Cleaning and descaling of metal surfaces;

Cleaning of injection molding machine injection shafts;

Removal of stains from concrete siding;

Residual fuel and rubber gaskets on rocket engines;

Removal of cylinder rings;

Maintenance of plant equipment: removal of fine dirt and hardened surfaces.

Grinding the inside of large round tubes:

1. Use the polishing machine to throw the rod, the rod head assembled with the corresponding size of the millipore wheel, or wheel-type abrasive belt, Shen into the inner wall, through the high-speed rotation, accompanied by the rotation of the steel pipe for polishing, respectively, the use of 60 #, 80 # millipore wheel.

2. Use polishing paste with cloth wheel for fine polishing. Increase the brightness.

II. Electrolytic Polishing

1. Electrolytic polishing is to take the pipe as a whole as the positive pole, insoluble metal as the negative pole, and at the same time put into the electrolytic tank. The chemical reaction generated by direct current is used to increase the brightness.

2. Electrolytic polishing will destroy the surface oxide layer, so it needs to be passivated with acid afterward to avoid rusting.