Aluminum alloy right angles are polished after welding, and doors and windows are polished smooth and flat.

Aluminum alloy is a special metal material, because of its plasticity, it can not be used with other metal solid performance.

Therefore, we use nylon sheets with both grinding power and polishing effect for sanding.

The tools used are: Angle grinder (electric/pneumatic), Velcro tray, and nylon sheet. We use 100mm products for all specifications.

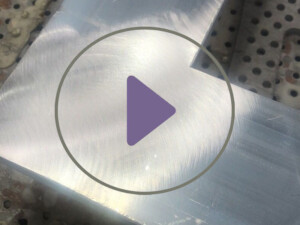

The grinding effect can be seen in the picture on the left. The grinding and roughing are carried out at the same time, so that the workpiece can be quickly finished grinding the weld.

Objects of post-welding grinding of aluminum alloy: excess weld scars, weld S-bend, plane grinding, weld porosity grinding, etc. Arc starting point, arc closing point, joints, weld black, etc.

Grinding for excess weld scars and weld S-bends caused during the welding process. Because aluminum alloy welds need to retain a certain amount of residual height, so that the material combination is not easy to break. Therefore, part of the unqualified residual height treatment, usually using a smaller range of grinding straight grinding machine with milling tool for.

When grinding is used mostly milling cutter side trimming, as far as possible to achieve the smoothness of the trimming place, no obvious angular marks.

Aluminum alloy plane grinding requirements is to make the surface of the weld flush with the base material, in the case of plane grinding, you can use an angle grinder with a nylon sheet, for plane grinding.

The low cutting force of the nylon sheet can polish the weld while ensuring that its small cutting force will not harm the base material. It also has a certain polishing function, so that the polished weld seam can be very well adapted to the base material.

Part of the process needs to retain the weld aluminum alloy material grinding, but the weld has a lot of pits, this is because of the welding of impurities or air caused by the bubble pit. If the bottom of this crater does not exceed the maximum depth allowed for the weld, this weld can be cosmetically corrected, if it does it must be repaired by welding the weld.

Welding black treatment, because the flux will be burned in the flame black, that is, high temperature volatilization out of the oxidized metal, this layer of oxidized metal will absorb moisture in the air, corrosion of the surface of the weld. Therefore, after the completion of welding, you need to deal with the welding black first.

Welding black treatment methods are, hand polishing using a cleaning cloth or angle grinder with black diamond, or use a sander with a wire brush.

The above part of the manual sanding, with the development of technology, automated sanding also began to emerge, the accuracy of automated equipment, so that the sanding process no longer become careful, the equipment pre-set data, so that the workpiece grinding can be completed quickly.

Therefore, the materials used in automated sanding equipment are all with strong cutting force, such as sandpaper, louvers, abrasive belts and milling cutters with machine arms.