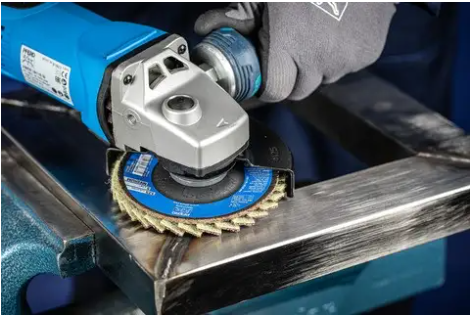

Welding, casting and all kinds of metal manufacturing industry, more in the surface transition, edge grinding, weld bevel processing and other professional fields are widely used. Especially suitable for stainless steel and high carbon steel grinding and polishing, good self-sharpening, synchronized chipping and grinding, can be efficient and rapid cleanup.

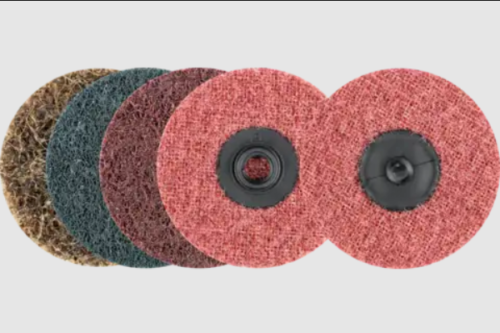

Non-woven nylon flap discs

Description

| designation | parameters |

|---|---|

| Product Dimensions: | 115mm*22mm |

| Abrasives: | nonwoven |

| Packaging specifications: | 10pcs/pack |

| Material quality: | inlet |

| Product particle size: | 80#~280# |

| Base material: | nylon fiber |

| Abrasive: | Aluminium oxide A |

| Dia. external: | 4 1/2 Inch / 5 Inch |

| Dia. hole; | 5/8-11 Inch / 7/8 Inch |

| Grit size: | 100 G / 180 M / 240 F |

| Mounting system: | Centre hole |

| RPM, max: | 12200 RPM |

| RPM, optimum, from: | 4600 RPM |

| RPM, optimum, to: | 5300 RPM |

| Width: | 3/4 Inch |

Welding, casting and all kinds of metal manufacturing industry, more in the surface transition, edge grinding, weld bevel processing and other professional fields are widely used. Especially suitable for stainless steel and high carbon steel grinding and polishing, good self-sharpening, synchronous grinding, can be efficient and rapid cleanup.

This product can be customized in size and grain number as required. The raw material is nylon fiber. Alternatively, other sizes can be designed according to the user’s grinding needs for the workpiece。

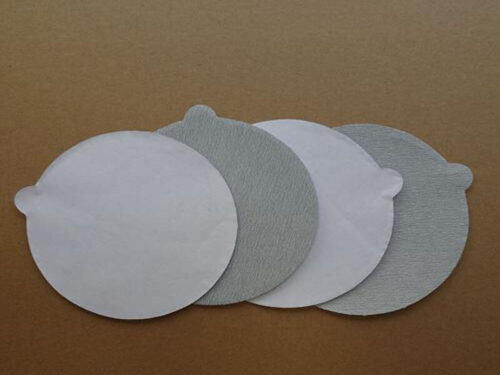

For universal coarse to fine grinding applications in industry and professional trades.

These are ideal for large stainless steel (INOX) surfaces.

Advantages

- Cost-effective due to high abrasive performance and durability.

- Creates a consistently high surface quality throughout the entire service life, as new sharp abrasive material is constantly exposed.

- Conforms to contours due to high flexibility.

Recommendations for use

- For the best performance, use with a recommended peripheral speed of 6,000-7,000 SFPM.

Safety notes

- For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

Workpiece materials

- Aluminum

- Brass

- Bronze

- Cast steel

- Cobalt-based alloys

- Copper

- Fibre-reinforced thermosetting plastics (GRP, CRP)

- Hardened, heat-treated steels over 370 HV (38 HRC)

- Nickel-based alloys (e.g. Inconell and Hastelloy)

- Stainless steel (INOX)

- Steel materials with a hardness > 54 HRC

- Steels up to 370 HV (< 38 HRC)

- Thermoplastics

- Titanium

- Titanium alloys

- Zinc

Applications

- Cleaning

- Deburring

- Roughening

- Step-by-step fine grinding

- Structuring (matt finishing, brush matting and satin finishing)

- Surface work

- Work on weld seams

Compatible power tools

- Angle grinder

- Cordless angle grinder

- Drive spindle

Usage Notes:

1,Before the use of various products, you need to check the degree of use of the product, in order to better fit the tool and workpiece.

2,Please make sure that the product is made of the correct material and the correct grain number before use, so as to avoid excessive wear on the workpiece.

3,If the product is to be used with machine tools, please make sure that the product is fixed correctly with the machine before starting the machine for testing and use.

4,Please make sure the storage environment of the product is dry and ventilated, and try not to stack and squeeze for better storage.

5,After using the products, please stack them in a unified way for better management of materials.

after-sales service

- From time to time to return to the customer to visit the use of the situation, and timely processing

- Understanding the needs of the customer, as well as helping to solve certain related problems

- Ensure product suitability for accurate product availability

- In case of quality problems, please provide pictures and detailed descriptions

- Replacement service if product quality is determined to be a problem

Why choose us?

Shanghai Jingjun Grinding, provides high quality materials and machinery, genuine imported raw materials. Processing and fabrication of required sizes for customers, fast, standardized production process.

Quality and quantity guaranteed for customers, wide range of grinding needs, special customization of abrasives, all to make grinding more efficient premise, abrasives and abrasives fit.

The fit of the abrasive to the tool makes the tool easier to handle. The fit of the abrasive to the workpiece, from rough grinding to fine grinding to polishing, one-stop supply of abrasives to grinding tools to machine tools.

Based on the principle of cost-effective, not high price, we will become a loyal ally of our customers and make them feel at ease with the production and processing of grinding consumables.

caveat

1, this site supplies imported products, are genuine imported materials, or imported raw materials. The same style part of the product can be divided into imported materials and domestic materials, please specify the required inquiry.

2, the site does not provide a unit price, all products according to demand, materials, technology and other factors, prices vary. Later will be provided in the form of quotations or contracts, etc. For details, please call / WeChat customer service advice.

3, my company provides grinding materials, grinding machine, grinding solutions one-stop service, details can be viewed in other categories or contact us for details, can provide product customization, grinding samples.

4,Main project of our company, grinding, polishing, drawing, deburring, de-welding and other processes abrasives and machine tools. When contacting us, please specify the name, size and quantity of the products you need. In order to provide you with detailed parameters in detail.