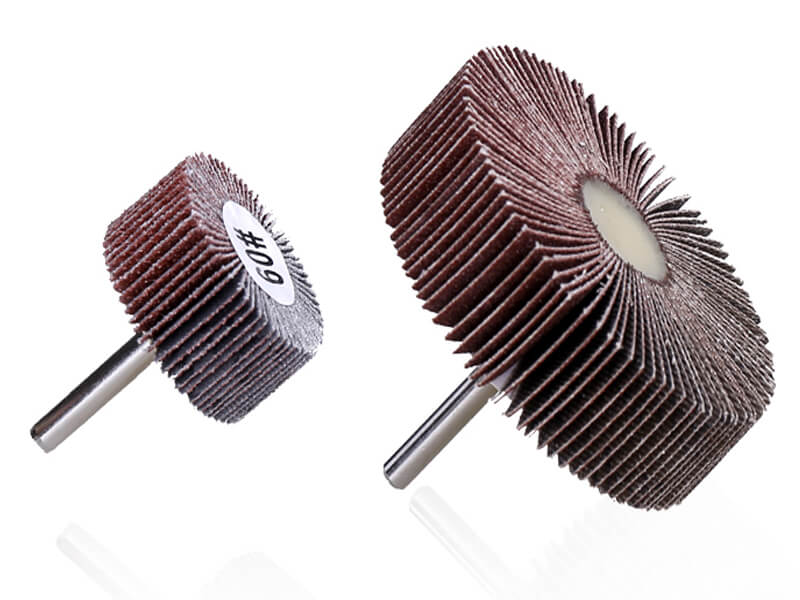

According to the specific size, it can be matched with pen grinder, straight grinder, angle grinder, etc. High toughness contributes to achieving the best grinding effect, and maintains excellent grinding effect and high grinding volume throughout the entire use process. Due to the special clamping installation system, when the tool is used facing downwards, it can process edges and corners at close range.

mounted flap wheels are made of non-woven polyamide abrasive, into which abrasive grain is integrated. The non-woven abrasive material is arranged in multiple radial flaps, with abrasive cloth interlayers. This flap structure improves stock removal and achieves a coarser surface finish.