Used for grinding and polishing small holes or grooves in parts of the workpiece. It is effective for metals such as stainless steel, titanium and high nickel alloys. Low noise and dust when grinding, and will not cause danger due to rusting and falling off like wire brushes. Provides users with a comfortable and safe operating environment.

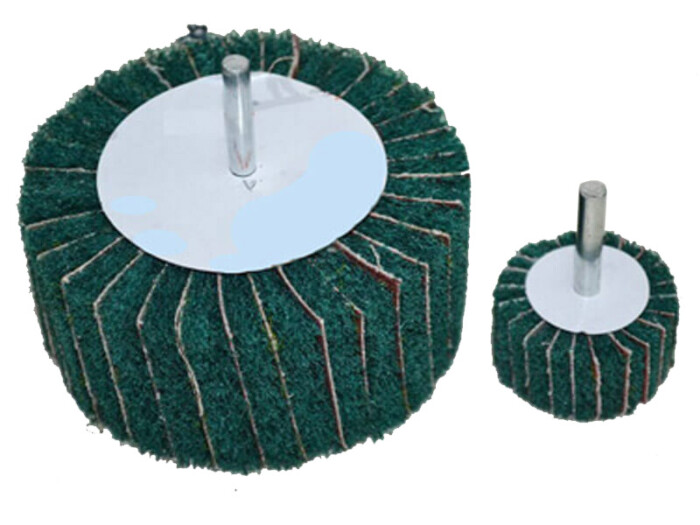

Interleaved Mounted Flap Wheel with handle

Description

| designation | parameters |

|---|---|

| Product Dimensions: | 25~60mm*25~50mm |

| Abrasives: | Non-Woven Fabrics / Detergent Cloths |

| Packaging specifications: | customizable |

| Material quality: | inlet |

| Shank Long: | 3mm~6mm |

| Base material: | nylon material |

| Grain size: | 180#/240#/320# |

| RPM: | 1500 |

| Abrasive: | Aluminium oxide A |

| Dia. external: | 1 1/2 Inch/ 1 Inch/ 2 3/8 Inch / 2 Inch /3 Inch /4 Inch |

| Dia. shank: | 1/4 Inch |

| Grit size: | 180 / 100 |

| Length, shank: | 1 1/2 Inch |

| RPM, max: | 20000 RPM |

| RPM, optimum: | 10000 RPM |

| Width: | 1 Inch / 2 Inch / ¾ Inch |

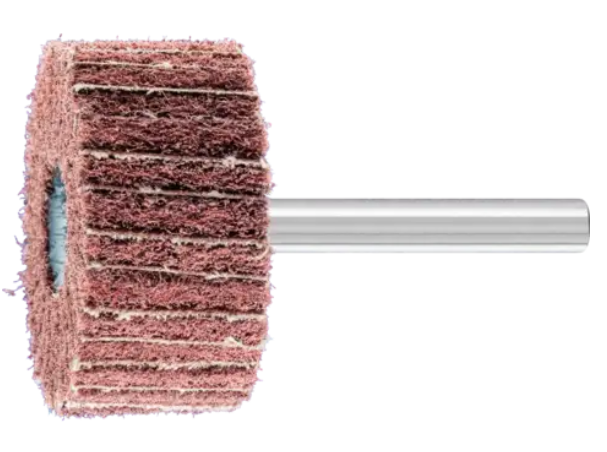

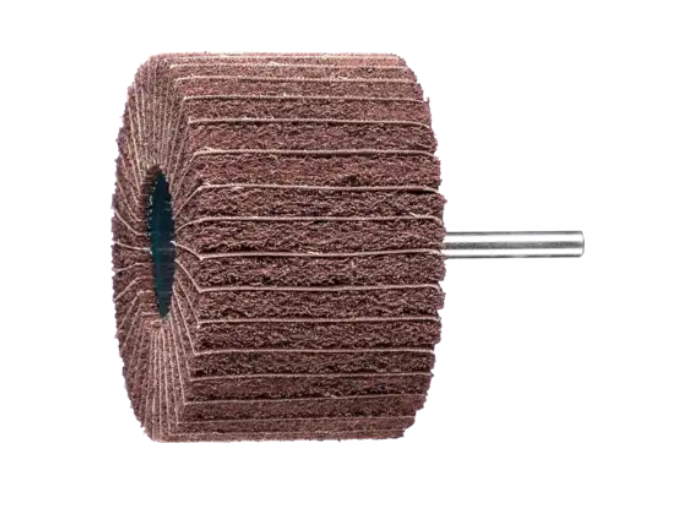

Interleaved Mounted Flap Wheel are made of non-woven polyamide abrasive, into which abrasive grain is integrated. The non-woven abrasive material is arranged in multiple radial flaps, with abrasive cloth interlayers. This flap structure improves stock removal and achieves a coarser surface finish.

Product Usage:

Flying wing wheel with handle is used in all kinds of electric grinder engraving grinder air grinder, deburring, grinding rounded position, surface grinding, one step to complete. To achieve the effect of deburring, rounding and surface grinding in the same step, saving time and speed. It is made of high tensile fiber combined with special viscose, which is resistant to water and oil. Uniform distribution of mineral grit keeps the processing effect stable and consistent. Flexible three-dimensional structure, will not damage the shape of the workpiece due to excessive cutting, resulting in scrap. Good heat dissipation performance, so that the surface of the workpiece will not be blackened, discolored or left with residual glue due to overheating during grinding.

Advantages

- Conforms to contours due to high flexibility.

- Cool grinding and low thermal load on the workpiece.

- The open structure and high flexibility of the non-woven material prevents loading.

Recommendations for use

- For the best performance, use with a recommended peripheral speed of 2,000-4,000 SFPM. This provides an ideal compromise between stock removal rate, surface quality, thermal load on the workpiece and flap wheel/cross buff wear.

Safety notes

- The maximum permitted peripheral speed is 6,300 SFPM.

- For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

Workpiece materials

- Aluminum

- Brass

- Bronze

- Cast steel

- Cobalt-based alloys

- Copper

- Fibre-reinforced thermosetting plastics (GRP, CRP)

- Hardened, heat-treated steels over 370 HV (38 HRC)

- Nickel-based alloys (e.g. Inconell and Hastelloy)

- Stainless steel (INOX)

- Steel materials with a hardness > 54 HRC

- Steels up to 370 HV (< 38 HRC)

- Thermoplastics

- Titanium

- Titanium alloys

- Zinc

Applications

- Cleaning

- Deburring

- Roughening

- Step-by-step fine grinding

- Structuring (matt finishing, brush matting and satin finishing)

- Surface work

Compatible power tools

- Flexible shaft drive

- Straight grinder

Instructions for use:

1,Before the use of various products, need to check the degree of use of the product, in order to better fit the tool and workpiece.

2,Please make sure that the product is made of the correct material and the correct grain number before use, so as to avoid excessive wear on the workpiece.

3,If the product is to be used with machine tools, please make sure that the product is fixed correctly with the machine before starting the machine for testing and use.

4,Please make sure the storage environment of the product is dry and ventilated, and try not to stack and squeeze for better storage.

5,After using the products, please stack them in a unified way for better management of materials.

After-sales service

- Visit customers from time to time and deal with the situation in time.

- Understand the customer’s needs and help to solve certain related problems.

- Ensure the applicability of the products, in order to provide accurate product supply.

- In case of quality problems, please provide pictures and detailed descriptions.

- If the quality of the product is determined to be problematic, provide replacement services.

Why choose us?

Shanghai Jingjun Grinding, provides high quality materials and machinery, genuine imported raw materials. We process and produce the required sizes for our customers, with fast and standardized production processes.

Quality and quantity guaranteed for customers, wide range of grinding needs, special customization of abrasives, all to make grinding more efficient premise, abrasives and abrasives fit.

The fit of the abrasive to the tool makes the tool easier to handle. The fit of the abrasive to the workpiece, from rough grinding to fine grinding to polishing, one-stop supply of abrasives to grinding tools to machine tools.

Based on the principle of cost-effective, not high price, we will become a loyal ally of our customers and make them feel at ease with the production and processing of grinding consumables.

Precautions

1, the supply of imported products, are genuine imported materials, or imported raw materials. The same style part of the product can be divided into imported materials and domestic materials, please specify the required inquiry.

2, the site does not provide a unit price, all products according to demand, materials, technology and other factors, prices vary. Later will be provided in the form of quotations or contracts, etc. For details, please call / WeChat customer service advice.

3, my company provides grinding materials, grinding machine, grinding solutions one-stop service, details can be viewed in other categories or contact us for details, can provide product customization, grinding samples.

4,Main project of our company, grinding, polishing, drawing, deburring, de-welding and other processes abrasives and machine tools. When contacting us, please specify the name, size and quantity of the products you need. In order to provide you with detailed parameters in detail.