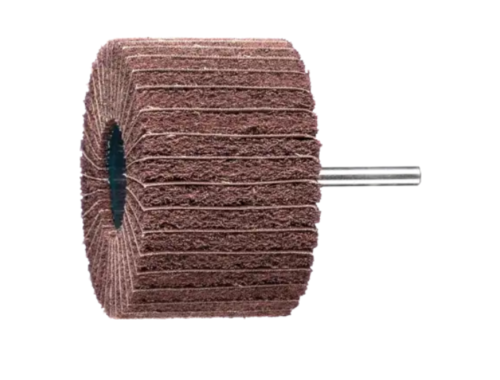

Non-woven finishing drums with customizable round and cross centers, or other shaped materials. Used in conjunction with a handheld wire drawing machine. For hardware stainless steel workpiece for wire drawing treatment. Strong cutting force, clear grain, high gloss, uniform line, no blackening, no need to add wax, wear-resistant, economical and durable.

Stainless steel, aluminum alloy, copper and iron parts and other materials. Kitchen utensils, subway cars, elevator panels, stainless steel freezers and other industries.