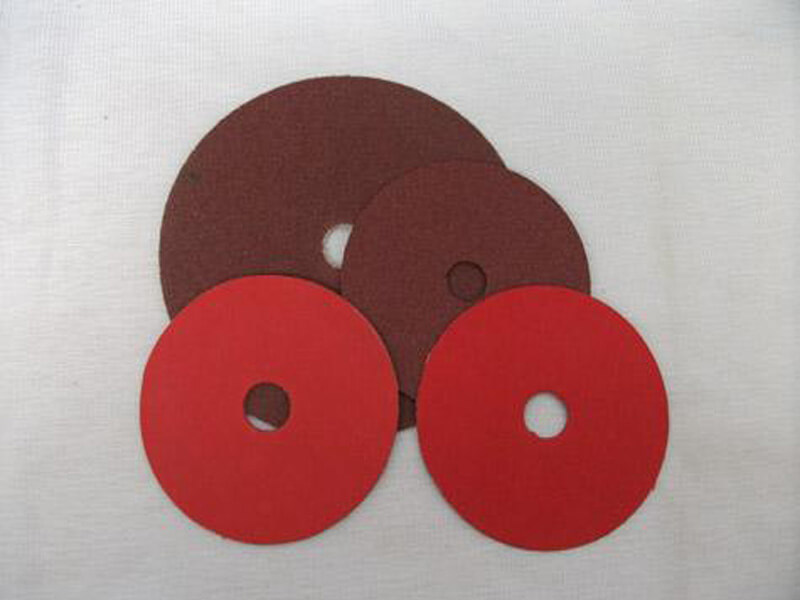

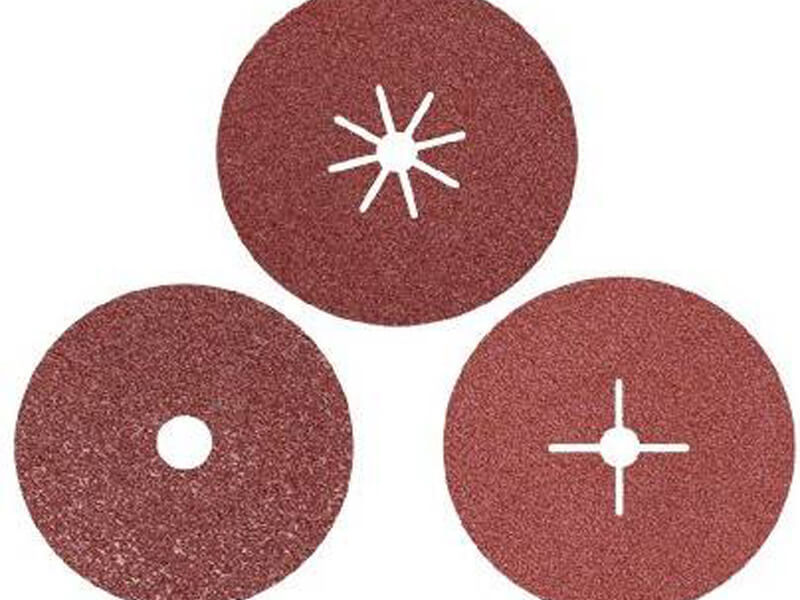

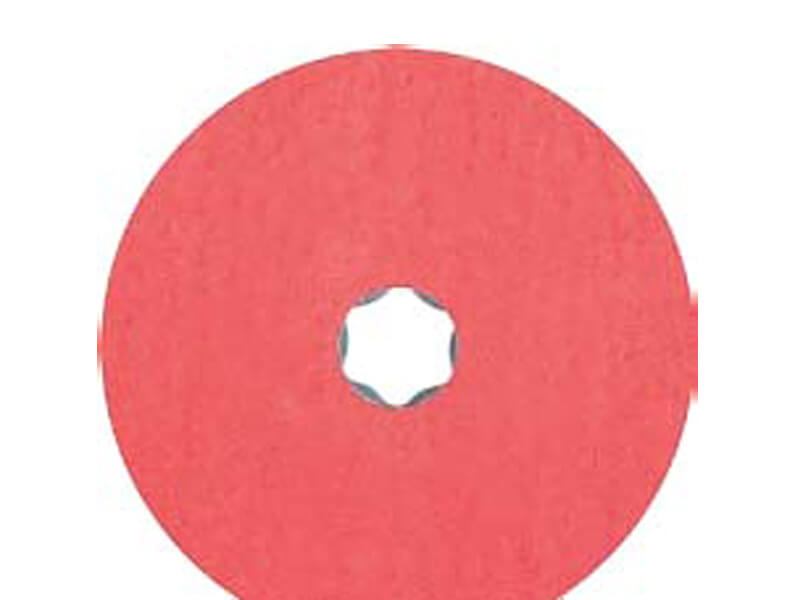

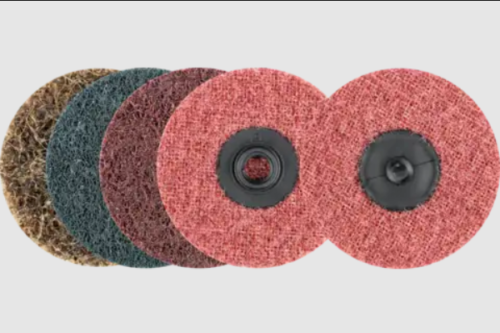

Aluminum core discs, cross core discs, round core discs, etc. The service life of these discs is several times longer than that of conventional discs. Good effect of uniform grit, clear grain, enhance the added value of the product. High efficiency High grinding rate, smooth operation, short grinding time.

Long-lasting surface finish during the service life. Low noise, anti-static, improve the working environment. There will be no high-temperature scorching phenomenon due to high-speed grinding work.

fibre discs

Description

| designation | parameters |

|---|---|

| Product Dimensions: | 100mm~180mm |

| Abrasives: | A-COOL/ Aluminium oxide A Ceramic/ Ceramic oxide grain CO-ALU / CO-COOL/ Silicon carbide SiC/ VICTOGRAIN-COOL/ Zirconia Z |

| Packaging specifications: | 25 tablets/box |

| Material quality: | inlet |

| Product particle size: | 36 mesh~80 mesh |

| Base material: | cardboard |

| Dia. external: | 5 Inch |

| Grit size: | 50 |

| RPM, max: | 12200 RPM |

fibre discs consists of a specially developed backing pad and a rugged mounting system at the back of the disc. The backing pad allows fibre discs to be used on most available angle grinders. The special geometry of the cooling slots ensures high air throughput, which considerably reduces the thermal load on the abrasive material and the workpiece. The quick-mounting system, rugged fixture, secure attachment of the disc and optimized cooling system help to provide up to 30% lower workpiece temperature, up to 25% increased stock removal, up to 30% longer disc life and improved utilization of the abrasive.

For universal grinding work from fine to very fine grinding on materials that do not conduct heat well, e.g. stainless steel (INOX) and aluminum. Active grinding additives in the coating substantially improve the stock removal rate, prevent loading, and result in cooler grinding.

Advantages

- Innovative quick-mounting system guarantees convenient handling and cool grinding

- High productivity due to long service life and very high stock removal rate.

- Consistent surface finish resulting from high-quality abrasives.

- Extremely quick and easy disc changes reduce process costs.

- With fibre discs, scratches caused by protruding clamping parts are prevented and very high utilization of the available abrasive is attained.

Recommendations for use

- with fibre discsbacking pads on commercially available angle grinders.

- Use the appropriate grinding oil for the material to significantly increase the service life and the abrasive performance of the discs.

- Soft and flexible grinding performance in face-down grinding.

Ordering notes

- Please order fibre discsbacking pads separately.

Safety notes

- The maximum permitted peripheral speed is 15,800 SFPM.

- For safety reasons, the maximum permitted rotational speed indicated must never be exceeded.

Workpiece materials

- Aluminum

- Stainless steel (INOX)

Applications

- Deburring

- Leveling

- Step-by-step fine grinding

- Surface work

- Working on edges

- Work on weld seams

Compatible power tools

- Angle grinder

- Cordless angle grinder

- Drive spindle

Scope of application:

1, Metal products such as stainless steel knives and scissors, cutlery, insulation cups.

2,Clock accessories, watch cases and straps.

3, Golf clubs, ball head surface treatment.

4, Hardware casting surface deburring.

5, Building hardware, hinge and locks.

6,Hardware lighting products and accessories.

7,Aluminum bicycle frame and rim polishing.

8,VCD panel and cell phone shell brushing.

9,Hardware sanitary ware products.

10,Electroplating products surface brushing treatment.

11,Aluminum heat sink deburring.

12, Stainless steel tube and strip surface drawing.

13,Grinding and polishing of all kinds of plates.

Instructions for use:

1,Before the use of various products, need to check the degree of use of the product, in order to better fit the tool and workpiece.

2,Please make sure that the product is made of the correct material and the correct grain number before use, so as to avoid excessive wear on the workpiece.

3,If the product is to be used with machine tools, please make sure that the product is fixed correctly with the machine before starting the machine for testing and use.

4,Please make sure the storage environment of the product is dry and ventilated, and try not to stack and squeeze for better storage.

5,After using the products, please stack them in a unified way for better management of materials.

After-sales service

- Visit customers from time to time and deal with the situation in time.

- Understand the customer’s needs and help to solve certain related problems.

- Ensure the applicability of the products, in order to provide accurate product supply.

- In case of quality problems, please provide pictures and detailed descriptions.

- If the quality of the product is determined to be problematic, provide replacement services.

Why choose us?

Shanghai Jingjun Grinding, provides high quality materials and machinery, genuine imported raw materials. We process and produce the required sizes for our customers, with fast and standardized production processes.

Quality and quantity guaranteed for customers, wide range of grinding needs, special customization of abrasives, all to make grinding more efficient premise, abrasives and abrasives fit.

The fit of the abrasive to the tool makes the tool easier to handle. The fit of the abrasive to the workpiece, from rough grinding to fine grinding to polishing, one-stop supply of abrasives to grinding tools to machine tools.

Based on the principle of cost-effective, not high price, we will become a loyal ally of our customers and make them feel at ease with the production and processing of grinding consumables.

Precautions

1, the supply of imported products, are genuine imported materials, or imported raw materials. The same style part of the product can be divided into imported materials and domestic materials, please specify the required inquiry.

2, the site does not provide a unit price, all products according to demand, materials, technology and other factors, prices vary. Later will be provided in the form of quotations or contracts, etc. For details, please call / WeChat customer service advice.

3, my company provides grinding materials, grinding machine, grinding solutions one-stop service, details can be viewed in other categories or contact us for details, can provide product customization, grinding samples.

4,Main project of our company, grinding, polishing, drawing, deburring, de-welding and other processes abrasives and machine tools. When contacting us, please specify the name, size and quantity of the products you need. In order to provide you with detailed parameters in detail.