Ergonomic grip design makes long time work easier, 5~6 inch tray is suitable for small and medium size flat surface sanding and polishing. Offset core orbital design, wider sanding area.

Eccentric plane polishing machine

Description

| designation | parameters |

|---|---|

| RPM: | 11000 |

| Abrasive Specifications. | 125*150mm |

| Gas flow: | 1.6(CFM) |

| Weight: | 0.9(kg) |

| Air intake connector: | 1/4(mm) |

| Eccentricity: | 5mm |

| Noise: | 80dba |

| Vibration: | 0.8m/s |

Perforated Sticky Tray

Ergonomic press handle

Sticky disk replacement

Pros:

1,One-handed push plate switch

2Velcro chassis, easy to replace sandpaper.

3, Eccentric bearing design, wider grinding range.

4,Precision movement, more durable to use

Customization: can be customized multi-vacuum hole machine, the main size is 5 inch, 6 inch. The number of holes is mainly 6 holes, other specifications, please consult the purchase specify.

Features: small size, high speed, high grinding efficiency, low noise, low vibration, no fatigue for long time use.

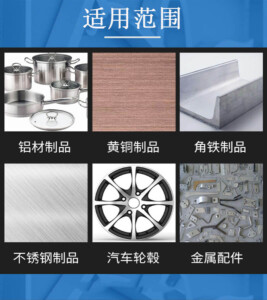

Scope: iron plate, wood, plastic, tire industry surface grinding, ships, automobiles, abrasives, aviation industry fine polishing, deburring, rust removal, paint removal and other operations.

Operating instructions:

1, before operation must carefully read the instruction manual, familiar with the basic operating methods, reasonable operation, to ensure maximum safety.

2,Clear the machine above and around the debris, do not allow any items placed in the feed port, to ensure that the machine is effectively grounded.

3,Determine the feeding speed and processing volume of the workpiece in advance, and prohibit the machine from working at excessive speed.

4, prohibit the use of defective products, before installation, to ensure that the installation of the surface of the smooth, no dirt, and check from time to time whether the lock is firm.

5,No safety door shall be opened during the operation of the equipment, and the operator shall try not to leave the workstation during the operation.

6, For regular cleaning and repairing and checking and adjusting parts, please turn off the power and stop the machine first.

After-sales service

- Visit customers from time to time and deal with the situation in time.

- Understand the customer’s needs and help to solve certain related problems.

- Ensure the applicability of the products, in order to provide accurate product supply.

- In case of quality problems, please provide pictures and detailed descriptions.

- If the quality of the product is determined to be problematic, provide replacement services.

Why choose us?

Shanghai Jingjun Grinding, provides high quality materials and machinery, genuine imported raw materials. We process and produce the required sizes for our customers, with fast and standardized production processes.

Quality and quantity guaranteed for customers, wide range of grinding needs, special customization of abrasives, all to make grinding more efficient premise, abrasives and abrasives fit,

The fit of the abrasive to the tool makes the tool easier to handle. The fit of the abrasive to the workpiece, from rough grinding to fine grinding to polishing, one-stop supply of abrasives to grinding tools to machine tools.

Based on the principle of cost-effective, not high price, we will become a loyal ally of our customers and make them feel at ease with the production and processing of grinding consumables.

Precautions

1, the supply of imported products, are genuine imported materials, or imported raw materials. The same style part of the product can be divided into imported materials and domestic materials, please specify the required inquiry.

2, the site does not provide a unit price, all products according to demand, materials, technology and other factors, prices vary. Later will be provided in the form of quotations or contracts, etc. For details, please call / WeChat customer service advice.

3, my company provides grinding materials, grinding machine, grinding solutions one-stop service, details can be viewed in other categories or contact us for details, can provide product customization, grinding samples.

4,Main project of our company, grinding, polishing, drawing, deburring, de-welding and other processes abrasives and machine tools. When contacting us, please specify the name, size and quantity of the products you need. In order to provide you with detailed parameters in detail.