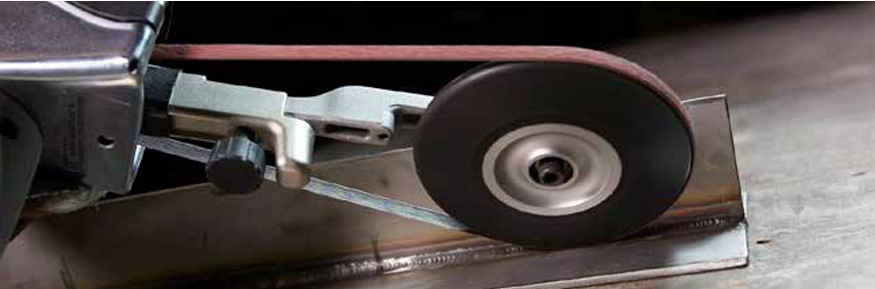

Offering a product life that is 50 to 200 percent longer than competitors’ belts, the cloth narrow backstand belt is the ideal product for coarse grit stock removal applications. Perfect for ensuring grain retention and minimal edge fraying, the belt comes equipped with a waterproof Y-weight polyester backing for durability and reliable results. It also features a lubricating coating that produces cool cutting action while ensuring minimal loading. When used on stainless steel, cobalt, chrome, titanium, and other metals, this belt improves material integrity while delivering a consistent finish.